When it comes to the installation or upgrade of electrical infrastructure, the type of panel chosen is one of the most critical decisions. For those seeking solutions in the Middle East, particularly in the United Arab Emirates, the term electrical panel manufacturers in UAE comes up very often. Among them, Al Arz Electrical Ware Trading is one of the leading companies in the United Arab Emirates when it comes to general trading and electrical panel supply.

Here’s a detailed guide to the major types of electrical panels, what makes them different, and how to choose which one is best for your application.

1. Main Distribution Panel – MDP

This is the main connection point where electricity enters a building or facility. At the main distribution panel, power is divided into several individual circuits and sub‑panels.

Characteristics:

- Generally sized for high current ratings.

- Includes a main breaker or disconnect switch.

- Supplies power to large loads or feeds sub‑panels in commercial/industrial setups.

When to use it: large buildings, industrial facilities, data‑centres, and other high‑demand environments.

Key considerations: should entail space for wiring, cooling/ventilation provisions, clear labeling, and future expansion capabilities.

2. Sub‑Distribution Panel (Sub Panel)

A sub-panel is a branch off the main panel. It allows for the distribution of power locally, closer to loads, rather than pulling everything through one big panel.

Characteristics:

- Receives feed via a dedicated breaker from MDP.

- Has its own circuit breakers for various loads.

- Smaller physical size than MDP, but still substantial.

When to use it: In large buildings, when you want to localize circuits – for example, separating lighting, air‑conditioning, and plug loads into separate zones.

Key considerations: Correct voltage drop, feeder cable sizing, and labeling of circuits.

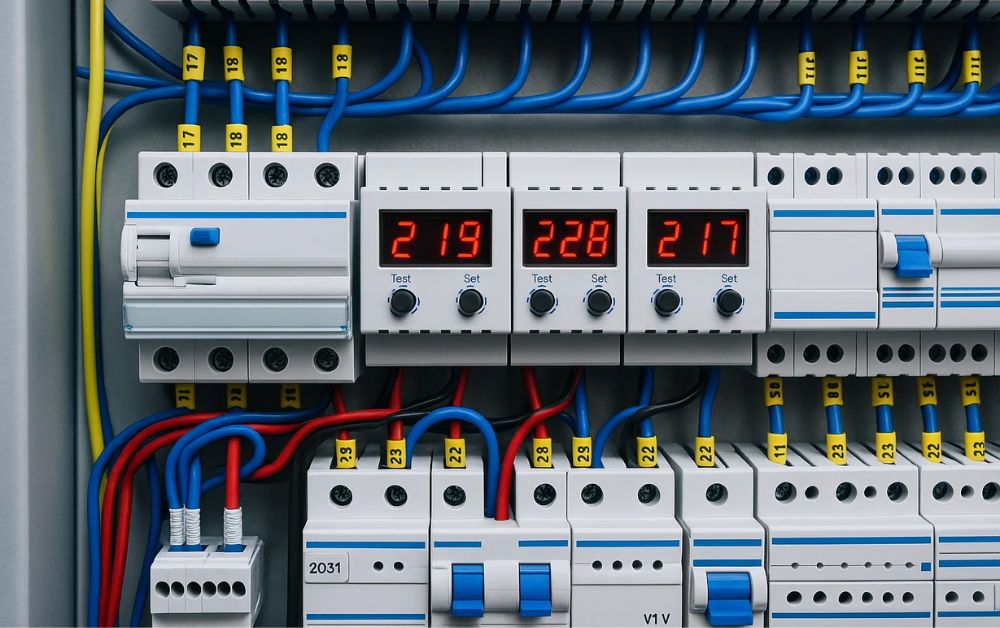

3. MCC panel – Motor Control Centre

That kind of electrical panel is specifically designed for motor loads: pumps, fans, conveyors, and other big machinery.

Characteristics:

- Contains starters and overload protection and often has VFDs for speed control.

- Typically modular, each motor gets its own section or bucket.

- Often includes monitoring meters or PLC control.

When to use: In industrial plants, manufacturing units, HVAC plants in large buildings, and utilities where many motors need central control.

Key considerations: thermal management (drives and motors generate heat), safety interlocks, space for additional motors in the future, isolation switches for maintenance.

4. Lighting Distribution Panel

Specialty panel devoted solely to lighting circuits, mainly used in commercial or institutional buildings.

Characteristics:

- Lower current ratings than MDP/MCC.

- Could include integration of contactors, timers, dimming control, and occupancy sensors.

- Easier to manage and label since only lighting circuits pass through.

When to use it: Hotels, hospitals, campuses, shopping centres — wherever complex lighting loads are present and need independent controls.

Key considerations: proper segregation of lighting and power circuits, enabling energy‑efficiency features, clear circuit labeling, and ease of maintenance.

5. Service Entrance Panel / Meter Combination Panel

This is often the panel in which the utility meter and main breaker reside, feeding branch circuits, in smaller residential or light commercial applications.

Characteristics:

- Combines the utility meter, main breaker/disconnect, and several branch breakers all in one enclosure.

- Often rated for standard residential currents: 100 A, 125 A, 200 A, etc.

When to use: Houses, small offices, light commercial premises that do not require large distribution infrastructures.

Key considerations: that the panel is rated for your local utility supply, provides surge protection, and is accessible for utility and maintenance work.

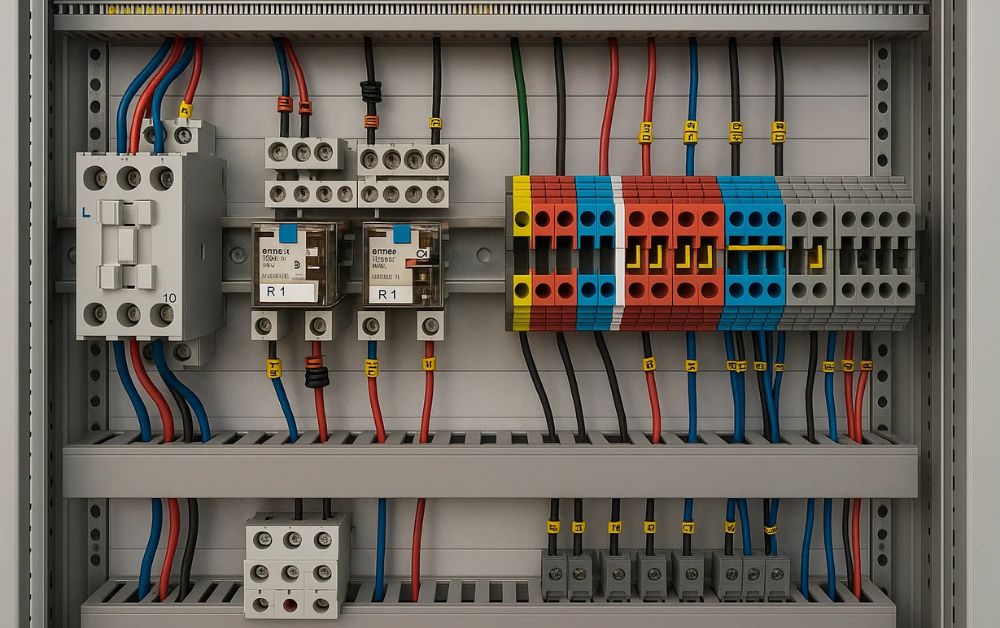

6. Specialty or Custom Panels (Control Panels, Switchgear Assemblies)

These panels are customized for a particular application, like explosion‑proof environments, remote instrumentation, switchgear automation, etc. Quite often, the manufacturers produce custom versions.

Characteristics:

- Engineered to specific standards that include hazardous area ratings, ingress protection IP ratings, and custom control functions, among others.

- Can include integrated PLCs, HMI displays, and communication modules.

When to use it: process plants, oil & gas facilities, chemical plants, offshore installations, smart buildings requiring automation.

Key considerations: include certification standards-e.g., IEC, UL, ATEX-cooling, access for maintenance, documentation, and future flexibility.

How to Choose the Right Panel for Your Needs

- Load calculation & future growth: Determine your current load plus planned expansions. Oversizing early can save headaches later.

- Electrical codes and standards: The panel must be in conformance with the local regulations (in the UAE, for example) and international standards.

- Space & environment: Indoor vs outdoor, ambient temperature, cooling/ventilation, accessibility for maintenance.

- Safety and protection features: include surge protection, arc‑fault detection, proper breaking capacity, and isolation switches.

- Brand & manufacturing reliability: Working with trusted manufacturers is essential. That is especially relevant when you search for electrical panel manufacturers in the UAE. Within that space, one of the leading names is Al Arz Electrical Ware Trading.

- Integration & controls: If you have automation, monitoring, or remote control, the panel must support those features.

- Maintenance and documentation: Access for service, clear labelling, spare space for additions, user manual/instructions.

- Budget versus lifetime cost: upfront cost is just one part – energy efficiency, avoidance of downtime, and flexibility in the future count.

Why Local Manufacturing and Expertise Matter

Working with locally or regionally-focused manufacturers or suppliers has its advantages, including faster delivery, awareness of local conditions- for example, the desert environment and high ambient temperatures in the UAE- accessibility for after-sales service, and familiarity with local utility requirements and certifications, when selecting electrical panel manufacturers in the UAE, check if they have custom fabrication, quality assurance, and regional support. Al Arz Electrical Ware Trading meets such criteria and is well-placed as a reliable local partner for electrical solutions in the UAE.

Conclusion

Understanding the different types of electrical panels is crucial, whether it is a new installation, upgrading of an existing system, or specifying equipment for a project. From main distribution panels and sub‑panels to motor control centres, lighting panels, service entrance panels, and custom control panels, each has its own purpose and design consideration. Having the right panel significantly enhances safety, efficiency, and scalability for your electrical infrastructure. Moreover, partnering with experienced and established vendors matters equally. So, when you search for electrical panel manufacturers in the UAE, remember that companies like Al Arz Electrical Ware Trading stand out as one of the UAE’s leading firms in the field of general trading and electrical panel solutions. Choose wisely today, and you’ll have fewer headaches tomorrow, while your electrical system will be robust, safe, and future-ready.