Be it chemical plants, oil refineries, grain storage facilities, or manufacturing units, most of the industrial workplaces face potential hazards where even a small spark or an overheated bulb may lead to a catastrophic fire or explosion. Specialized lighting, therefore, is not a luxury but a dire necessity. Whether you are looking for safe, compliant, and proven lighting solutions or are in need of proper fixtures and guidance, an experienced explosion proof Light Supplier in UAE can be relied upon. One such reliable name is Al Arz Electrical Ware Trading. It is among the leading companies of the UAE in the sphere of general trading.

Here, we discuss how explosion‑proof lighting works, why it’s considered crucial for workplace safety, and how the proper investment in lighting can do much to reduce various accidents, protecting lives and resources alike.

What Is Explosion‑Proof Lighting?

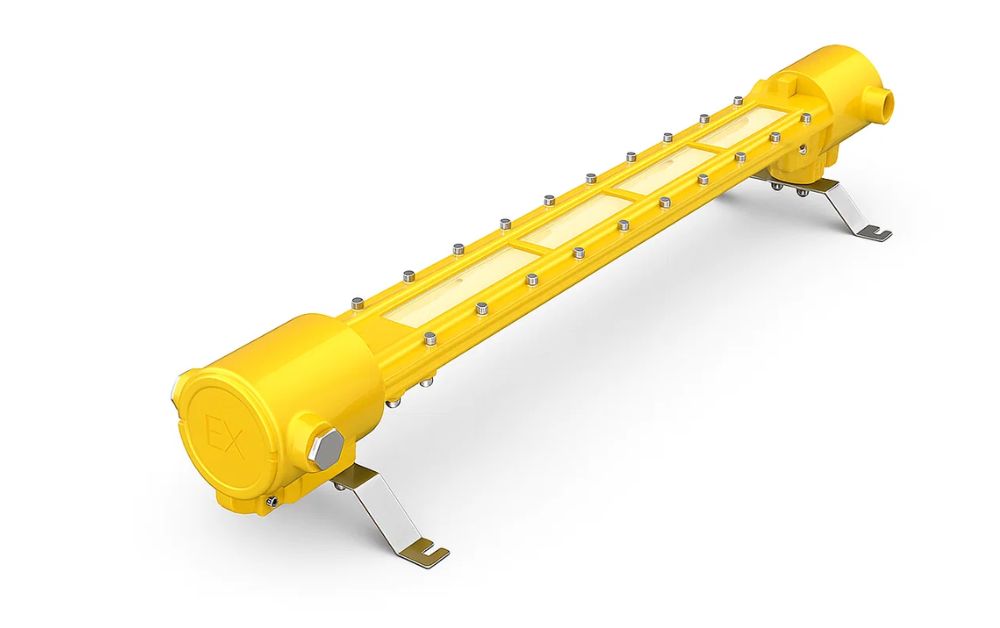

Explosion-proof lighting — sometimes called “hazardous area lighting” or “Ex-lighting” — includes light fixtures that are specially engineered to operate safely in environments where flammable gases, vapors, or combustible dusts may be present.

Unlike standard lighting fixtures, which can ignite a volatile atmosphere if a spark occurs or if the housing overheats, explosion‑proof lights are designed to contain any internal spark or heat. Their enclosure is rugged, generally manufactured from metals like aluminum, stainless steel, or other robust metals, and features tight seals, impact‑resistant glass, vibration‑resistant design, and more.

In other words, they don’t prevent an explosion from occurring elsewhere; they prevent the light itself from being the ignition source.

Why Standard Lighting is a Danger in Hazardous Workplaces

In hazardous environments — where flammable gases, vapors, or fine combustible dust are present — even a minor electrical fault or overheated standard lamp can provide just enough heat or a small spark to ignite an explosion.

These conditions are typical for industries that include petrochemical processing, chemical manufacture, paint booths, mining, grain storage, pharmaceutical plants, and others where volatile substances or combustible dust may accumulate.

What’s more, conventional lighting often doesn’t have the needed sealing or heat containment. Over time, dust, moisture, or corrosive elements can degrade components and further increase the danger of ignition. In such high‑risk zones, standard industrial lighting simply doesn’t meet the demands for safety.

How Explosion‑Proof Lighting Works: Safety by Design

1. Robust, Sealed Enclosures

Explosion‑proof fixtures are designed in thick, corrosion‑resistant housings – usually aluminum or stainless steel – to withstand impact and moisture, dust, and harsh conditions.

Every joint, lens, and fastener are sealed tightly to avoid ingress of gas, dust, or vapor. The usual glass applied is of the tempered or borosilicate type that resists high heat, impact, and pressure changes.

2. Containment of Sparks and Heat

If an internal fault occurs — such as a loose wire or malfunctioning bulb — any spark or heat produced remains within the fixture. Specialized “flame‑paths” and gasketed seals cool or trap any hot gases before they can exit the fixture.

The core principle of this containment is to prevent the fixture from becoming the ignition source for a surrounding potentially explosive atmosphere.

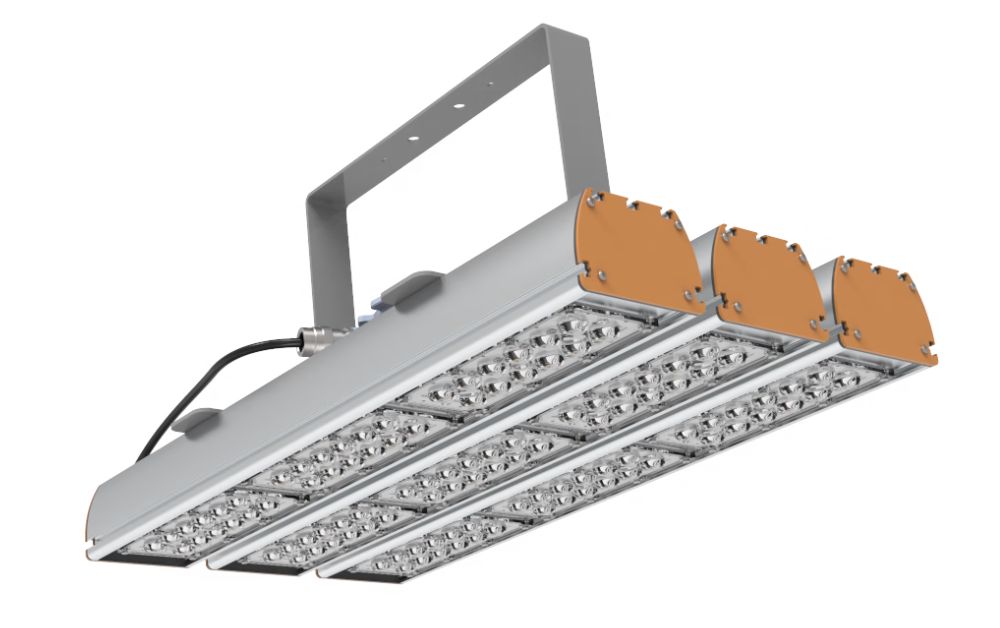

3. Heat Control & Low‑Heat Light Sources (LED)

These days, explosion‑proof lights are frequently produced using modern LED technology, which makes far less heat than conventional incandescent or metal‑halide light bulbs. Less heat means less risk of igniting flammable gases or dust.

Not to mention, LEDs are energy-efficient and longer-lasting, so you won’t need to stay on top of maintenance as often or be concerned about the internal components coming loose.

Benefits of Explosion‑Proof Lighting: Preventing Accidents Before They Happen

1. Drastically reduces fire and explosion risk

By eliminating sparks, heat leaks, and ignition sources, explosion‑proof lighting significantly reduces the chances of disastrous fires or explosions.

2. It improves visibility and reduces operational accidents

Good lighting improves visibility, allowing workers to see walkways, equipment, obstacles, or hazards clearly. It helps avoid slips, trips, falls, or operational mistakes.

Bright, stable illumination also enables operators to monitor machinery and detect leaks, spills, or other hazards early – before they become significant hazards.

3. Durability, Reliability & Lower Maintenance Costs

Explosion‑proof fixtures are designed to be tough in harsh industrial environments that include dust, moisture, chemicals, and mechanical stress. This durability will provide longer service life, fewer replacements, and reduced maintenance costs.

By using energy‑efficient LEDs, for example, companies can reduce electricity bills and improve sustainability — while continuing to meet safety standards.

4. Safety Regulations & Standards Compliant

Many countries have legislation insisting that lighting in hazardous zones must meet recognized standards; often these refer to frameworks like ATEX Directive 2014/34/EU or IEC 60079, or similar national and local statutes.

Using certified explosion-proof lighting helps organizations meet safety legislation, minimize liability, and protect both personnel and infrastructure.

Choosing the Right Explosion-Proof Lighting: What to Look For

Here are a few essential things to consider when selecting explosion‑proof lighting for dangerous industrial spaces:

- Hazard Classification: Determine if the atmosphere is gas, vapor, or dust. The various zones and divisions — gas‑hazard zone, dust‑hazard zone — will help you determine what kind of fixture to buy and the rating that it should have.

- Certification & Compliance: Always select lights that are certified to known standards like ATEX / IEC / UL-type, etc., which is a guarantee for all safety norms.

- Durability & Construction: Shop fixtures that are constructed of sturdy metal housings, impact-resistant glass, strong gaskets, and corrosion-resistant materials when you’re working in demanding industrial environments.

- Proper Light Source: LED vs Conventional: Use explosion-proof LED lighting where possible; they’re cooler, last longer, save electricity, and are less of a fire hazard.

- Maintained and Monitored: Explosion-proof lighting is no exception; just because they are explosion-proof doesn’t mean that this is an infrequent event – regular maintenance checks for seals, the integrity of the glass, electrical connections, etc., as well as to clean off dust or moisture, can help to ensure safety over time.

Why Partnering with a Trusted Supplier Matters

Installing explosion-proof lighting is no trivial issue. Expert knowledge of hazardous-area classifications, correct fixture types, firing proofs, certifications, and maintenance protocols is required. A trusted supplier can guide you in picking the right fixtures that match your facility’s risk profile.

That is where Al Arz Electrical Ware Trading comes in. Being one of the reputed firms in the UAE general trading sector, they have experience in sourcing and supplying explosion-proof lighting solutions fitted for demanding industrial environments. Their expertise in the industry helps you to get fixtures compliant with the necessary certifications and apt for your workspace hazards.

With a trusted supplier, the risk of buying poor-quality lighting that may result in non-compliance, life-threatening accidents, or costly downtime is significantly reduced.

Conclusion

Workplace accidents, in particular those involving fire or explosion, are not merely tragedies; they bear costly consequences, financially, legally, and reputationally. Correct safety planning consists of the elimination of ignition sources where hazardous atmospheres could form. That’s precisely where explosion‑proof lighting plays a non‑negotiable role. We help you invest in certified, well-designed explosion-proof lights that protect lives, assets, and operations. For organizations in the UAE, looking out for dependable hazardous-area lighting requires the partnership of a trusted explosion-proof light Supplier in the UAE as a crucial step toward safety, and one great option is Al Arz Electrical Ware Trading, a leading name in general trading and industrial solutions. Safety begins with awareness, but is secured through reliable, compliant lighting. Choose wisely, and give your workforce the protection they deserve.