In today’s Industry 4.0 environment, signal cables are the lifelines on which control commands, sensor information, and real-time communication ride in automated systems. Selecting the appropriate signal cables is vital in ensuring consistent performance, safety, and effective data transfer in industrial automation configurations. Whether you are upgrading your factory floor or installing a new industrial control system, informed decisions on signal cables can help avoid expensive downtime and communication failures. For companies in the UAE, procuring from trusted suppliers like Al Arz Electrical Ware Trading—a well-known name among transformer suppliers in UAE—guarantees quality and durability in signal cables as well as related electrical parts.

Introduction to Signal Cables in Industrial Automation

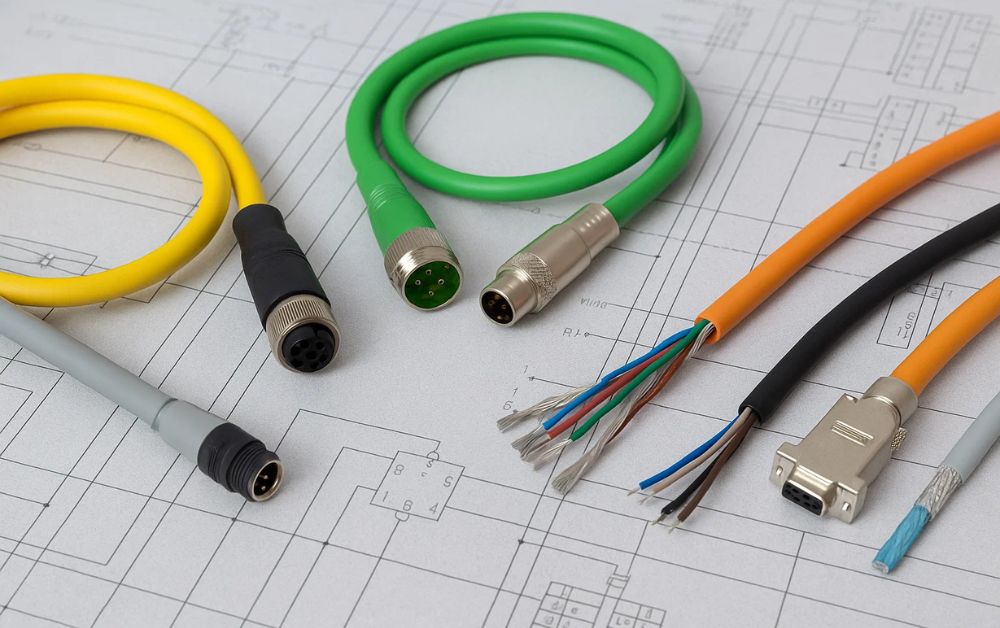

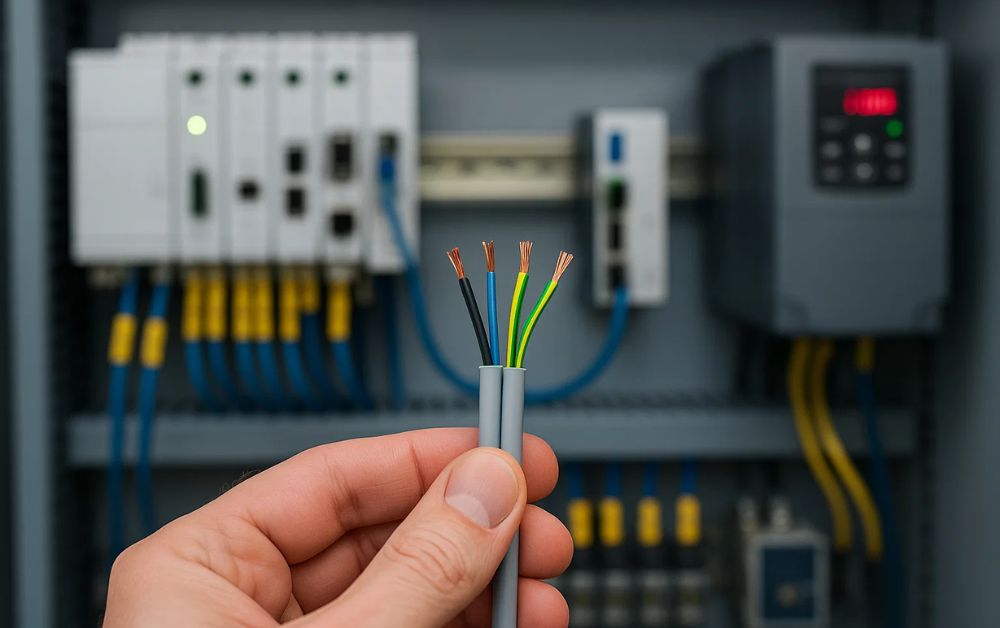

Signal cables used in industrial settings are connectors between actuators, sensors, controllers, and other automation devices. They are intended to transmit low-voltage signals and not high power, which makes them best suited for the transmission of data and commands. Unlike typical electrical wiring, these cables are required to resist electromagnetic interference (EMI), vibration, heat, and even chemical exposure in noisy industrial settings.

Selecting the wrong type of signal cable can degrade system performance, cause repeated faults, and raise maintenance expenses. Therefore, knowing the critical parameters and choosing the correct wires engineered for your application is crucial.

Essential Factors to Consider When Buying Signal Cables

1. Signals Being Transmitted

The initial step in the process of selecting signal cables is to define the kind of signals they have to transmit:

- Analog Signals: These cables transport voltages that change continuously over time. They are prone to interference and need shielding.

- Digital Signals: These send discrete binary information and are comparatively more robust, but are still helped by shielding in noisy surroundings.

- Data Communication: Fieldbus protocols such as PROFIBUS, CANBUS, or Industrial Ethernet require cables with precise impedance and frequency specifications.

It ensures the cable matches the signal type to minimize signal degradation and maintain increased system integrity.

2. Shielding Needs

Working environments are full of EMI sources like motors, variable frequency drives (VFDs), and transformers. Noise is reduced, and signal corruption is avoided by shielding:

- Foil Shielding: Inexpensive and effective at blocking high-frequency EMI.

- Braided Shielding: Stronger and better for low-frequency EMI and mechanical shielding.

- Double Shielding: Offers the ultimate protection and is ideal for high-interference environments.

The use of shielded cables is essential when signal integrity is critical, such as in high-speed data communication or sensitive analog applications.

3. Cable Construction and Materials

The construction of a signal cable determines its flexibility, resistance to wear and tear, and longevity in industrial settings. Key elements to evaluate include:

- Conductor Material: Copper is most commonly used due to its high conductivity.

- Insulation: PVC, PE, or Teflon provides different levels of heat resistance and flexibility.

- Jacket Type: Outer jackets have to be resistant to oil, chemicals, and abrasion. For instance, PUR (Polyurethane) jackets are extremely tough for harsh environments.

4. Operating Temperature and Environmental Conditions

Signal cables need to be able to withstand the operating environment:

- Temperature Range: Select cables qualified for the expected ambient and operating temperatures.

- Chemical Exposure: In spaces where cables are subject to oils, solvents, or cleaning chemicals, chemical-resistant jackets are required.

- Mechanical Stress: Cables within moving equipment must be capable of continuous flexing and be compatible with drag chains.

5. Adherence to Industry Standards

Verify the signal cables meet international and local standards, including:

- UL/CSA Certification: For fire performance and safety.

- CE Marking: For European conformity.

- ROHS Compliance: Verifies that the cable is free from hazardous materials.

For UAE projects, working with providers that recognize regional compliance needs is also essential. Reliable transformer suppliers in the UAE, such as Al Arz Electrical Ware Trading, typically stock signal cables that are both globally and locally compliant.

6. Distance and Voltage Drop

Although signal cables transmit low-voltage currents, extended cable lengths have the potential to cause voltage drops or signal attenuation. The use of appropriate conductor size and impedance in the selected cables ensures signal integrity over longer lengths.

7. Application-Specific Requirements

Various industrial applications require various signal cable types:

- Fixed Installations: Regular cables with standard insulation and no flex demands.

- Robotic Arms or Moving Machinery: Very flexible or drag chain cables.

- Clean Rooms: Low-particulate, halogen-free cable.

- Outdoor Use: Weatherproof, UV-resistant cables.

A customized solution guarantees maximum performance, safety, and lower maintenance.

Where to Source High-Quality Signal Cables in the UAE

Selecting the correct supplier is just as vital as choosing the proper cable. If reliability, compliance, and durability are considerations, it makes sense to source from a reliable supplier like Al Arz Electrical Ware Trading. As one of the established transformer suppliers in UAE, they offer a wide range of industrial-grade cables, including signal cables, power cables, and control wiring solutions, sourced from globally reputable manufacturers.

Their team can also assist in evaluating your industrial environment and recommending the most suitable cable types, ensuring your automation systems run smoothly and efficiently.

Conclusion

In every industrial automation system, signal cables are not just accessories but essential components that facilitate communication across systems. Data integrity, system efficiency, and safety—by selecting the appropriate signal cable, you can make a real difference. Considering signal type, shielding, build, environment, and compliance will enable you to make an informed decision for your installation.

For industrial establishments and companies in the UAE, partnering with seasoned providers like Al Arz Electrical Ware Trading—the name that resonates with quality among transformer suppliers in the UAE—guarantees that you not only receive high-quality signal cables but also receive seasoned advice and assistance throughout your project.

Investing in the correct signal cable today will deliver consistent performance, minimize downtime, and enhance automation tomorrow.