When it comes to powering homes, businesses, & industries, electrical cables are the unsung heroes of modern infrastructure. However, picking the correct cable is not just about performance—it is about ensuring safety & meeting regulatory standards. For anyone in the UAE, whether you’re a contractor, business owner, or homeowner, understanding electrical cable standards and labels is key to making smart, informed decisions. This guide will aid you navigate through the essential standards & labels to look for when sourcing cables and why it matters to work with reliable electrical cable suppliers in UAE.

What Cable Labels Tell You

When you are picking out cables, labels can give you a quick snapshot of important details like voltage ratings, material types, & more. Understanding these labels is crucial to making the right choice. Here are some of the most common labels you’ll come across:

1. Voltage Rating

This shows the maximum voltage a cable can safely carry. Labels like 300/500V or 0.6/1kV are commonly used for low to medium voltage applications. It is crucial to pick a cable with a high enough voltage rating—choosing one that’s too low could lead to insulation breakdowns & serious hazards.

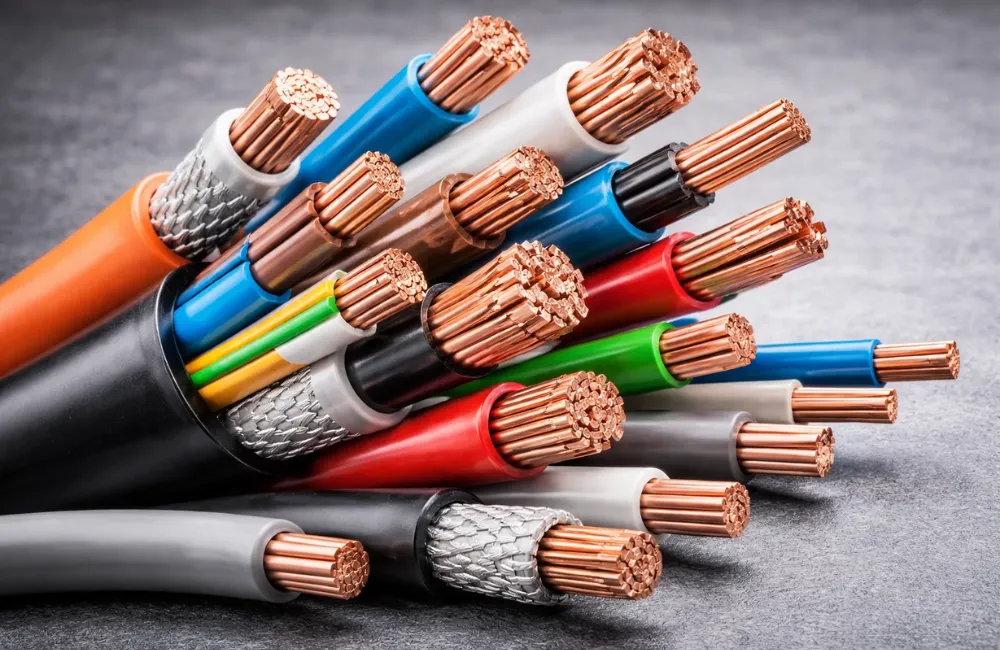

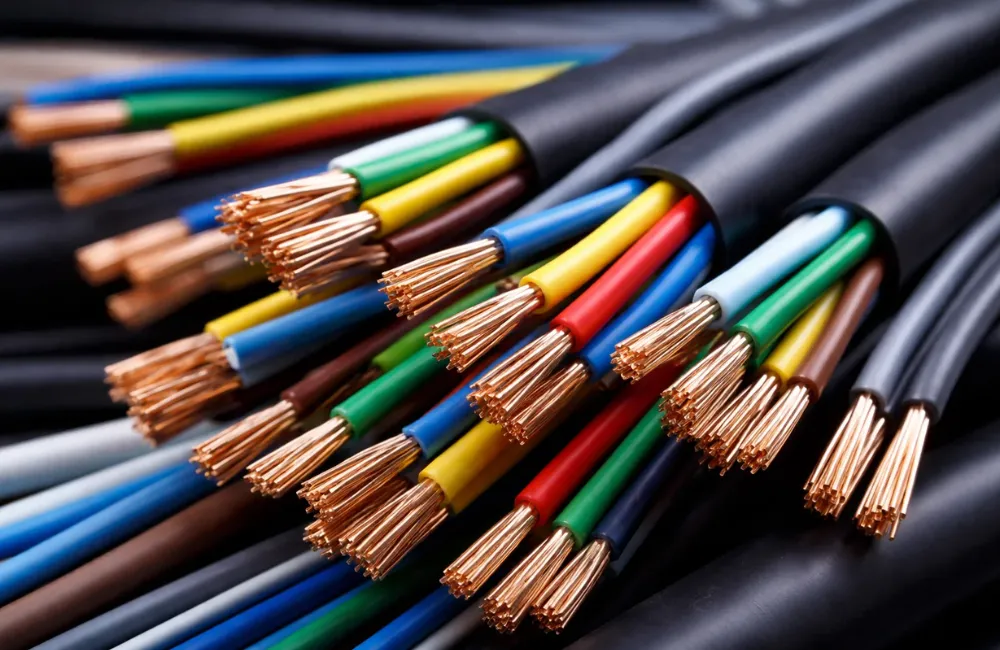

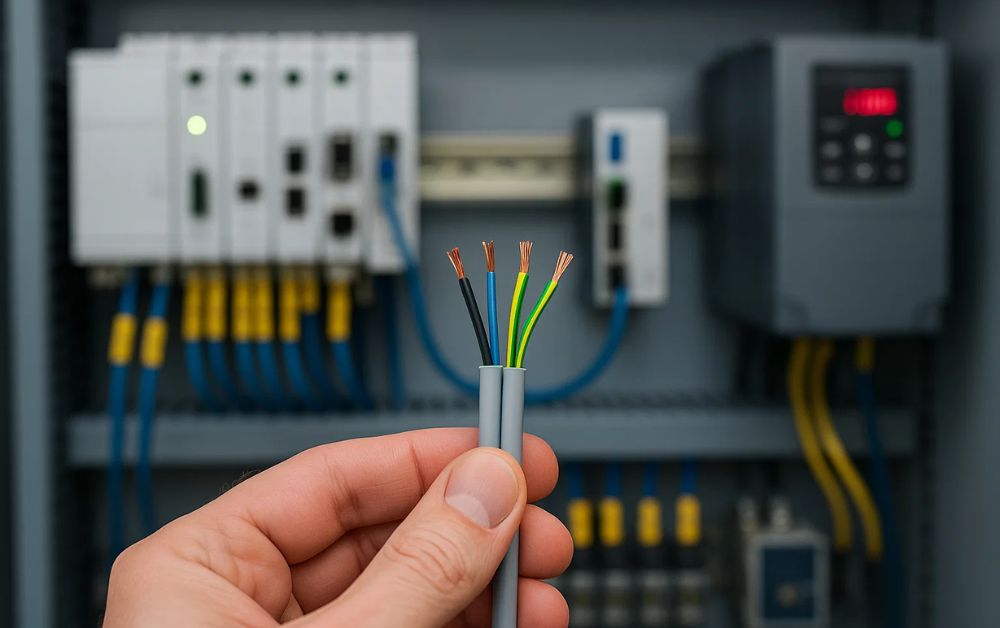

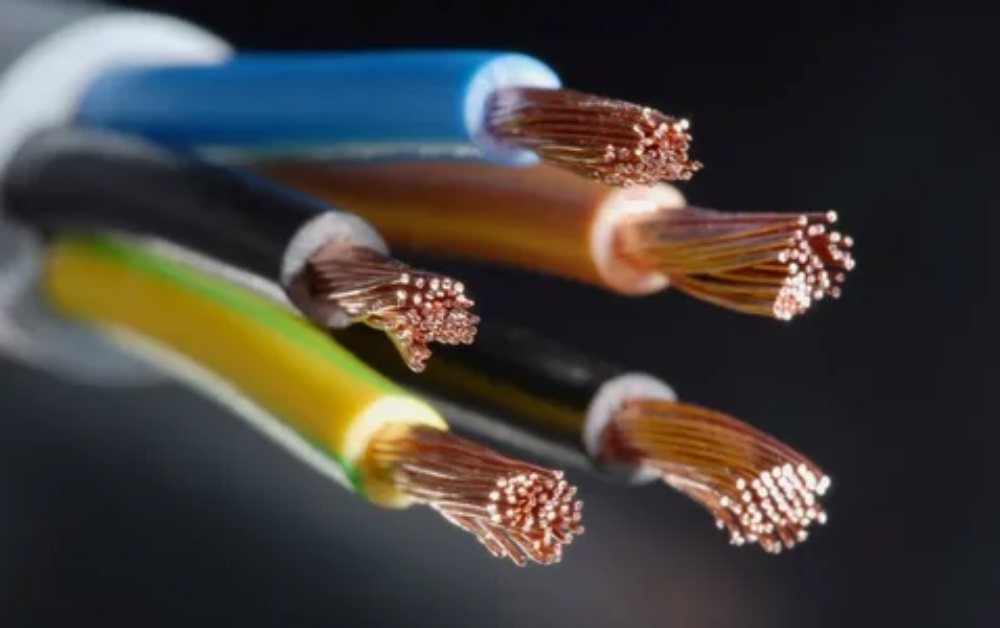

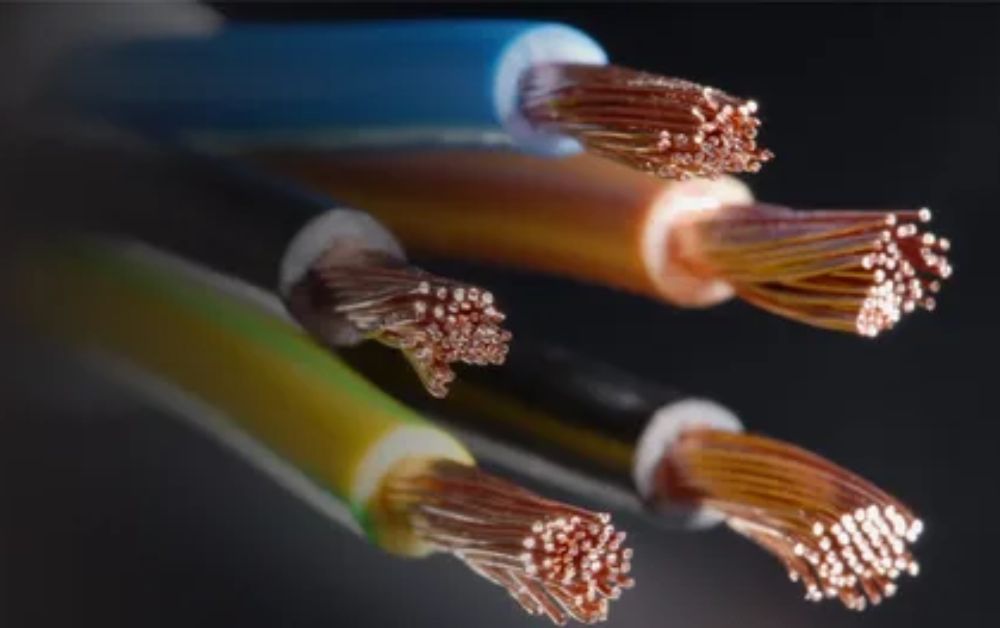

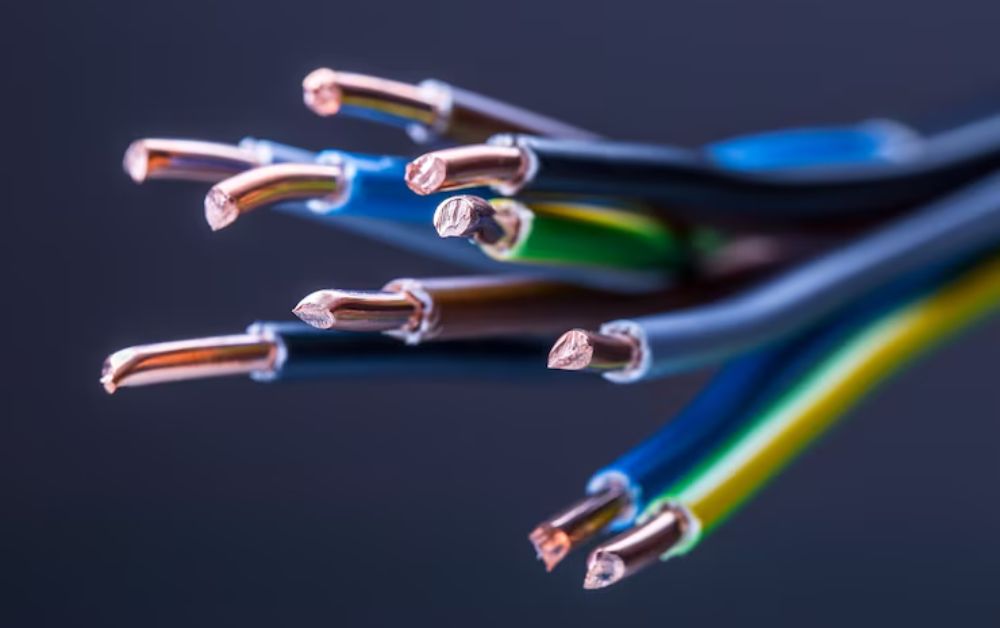

2. Conductor Material

The conductor material is usually copper (Cu) or aluminum (Al). Copper is favored for its conductivity & flexibility, while aluminum is lighter & more cost-effective for long-distance use.

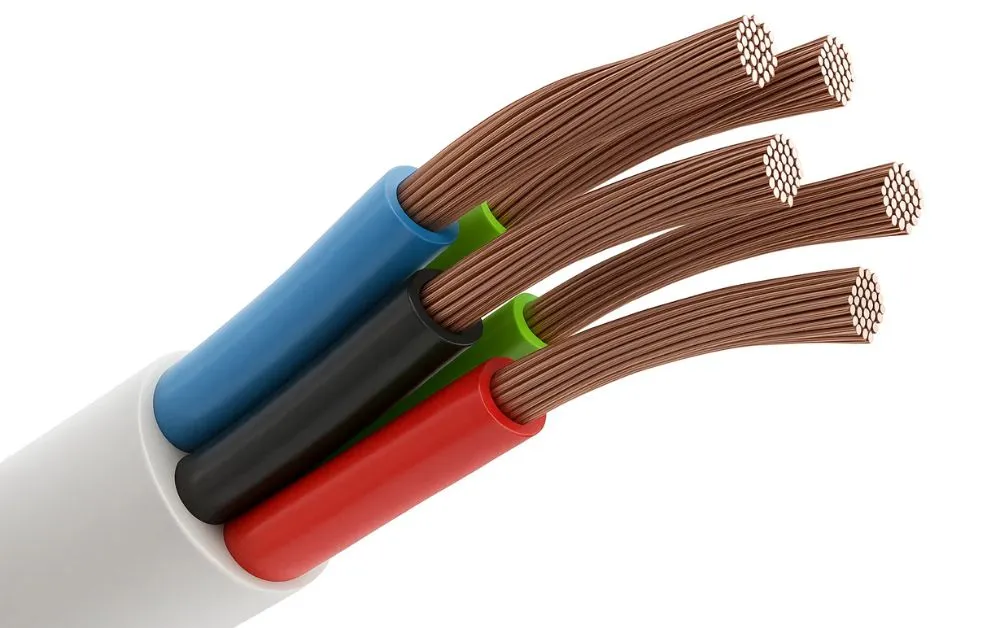

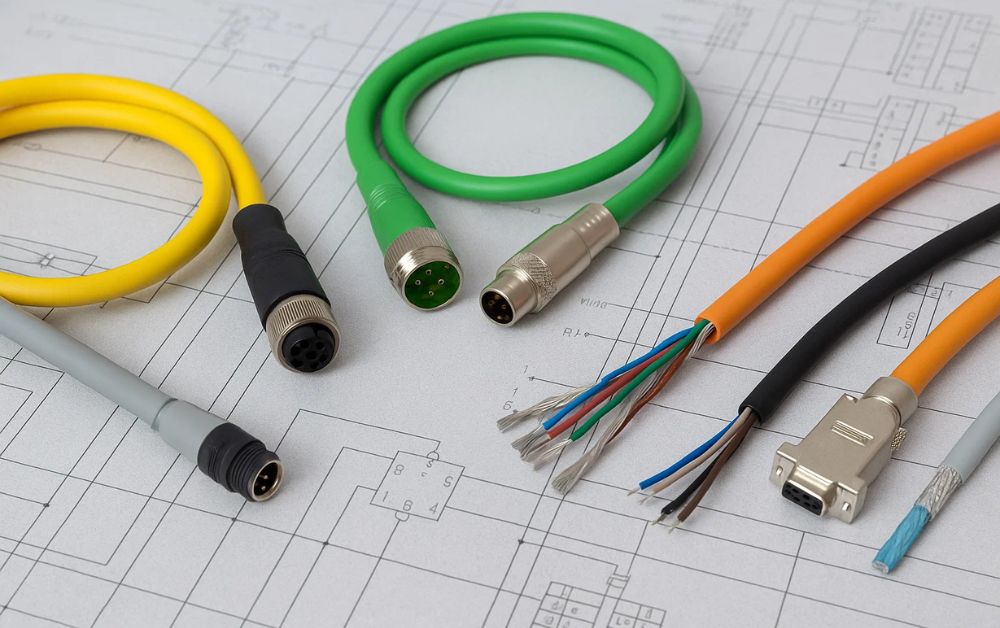

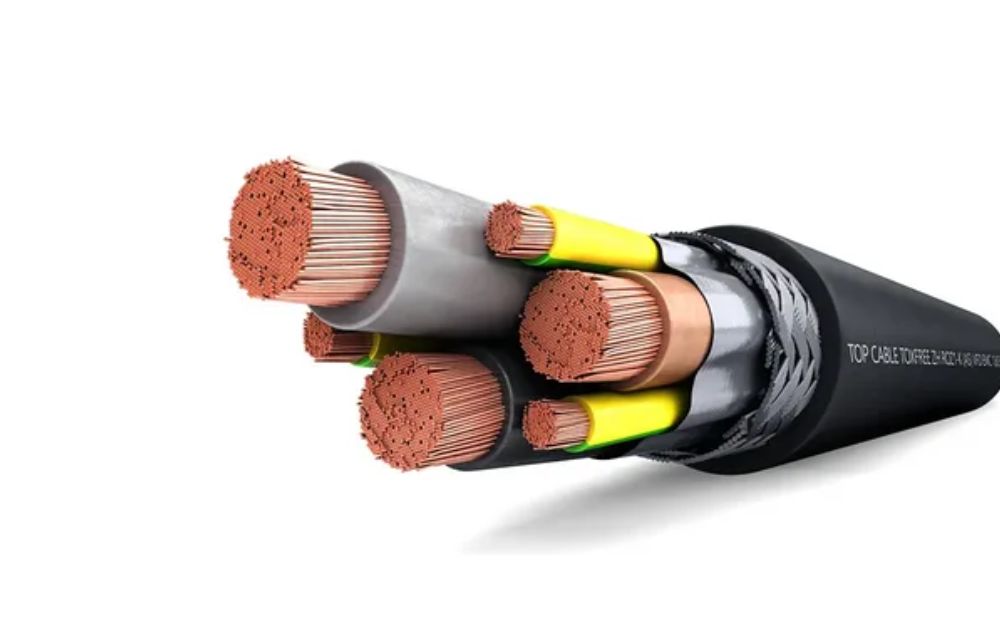

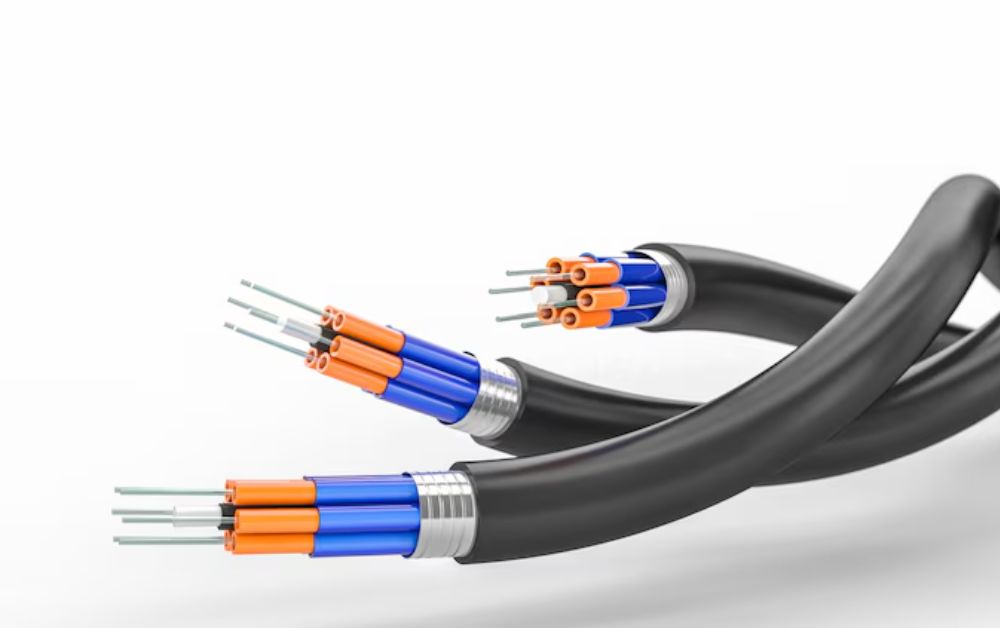

3. Insulation Type

The insulation material protects the conductor & prevents electrical shocks. Here are some common types

-

- PVC (Polyvinyl Chloride): Widely used for general wiring. Affordable and easy to work with.

-

- XLPE (Cross-Linked Polyethylene): Resistant to higher temperatures & more durable, making it ideal for industrial environments.

-

- LSZH (Low Smoke Zero Halogen): These cables produce less smoke and toxic fumes in case of fire, which is essential in places like public buildings and confined spaces.

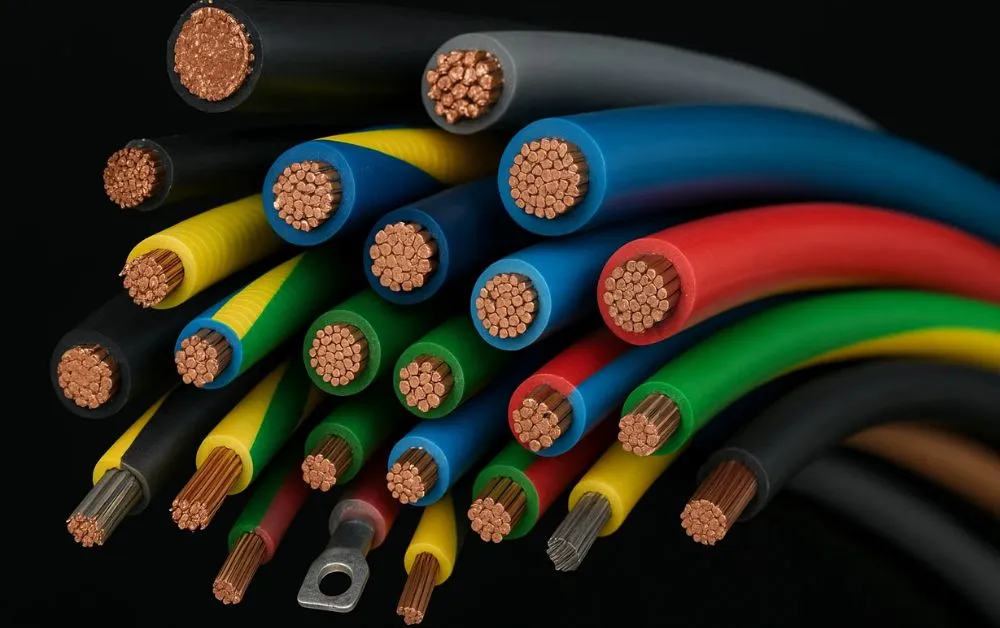

4. Cable Size and Current Rating

This is the cross-sectional area of the conductor (measured in mm²), and it tells you how much current the cable can safely handle. For example, 4 mm², 25A means the cable is 4 square millimeters in size & rated for 25 amperes. Picking the right size prevents overheating & energy loss.

5. Fire Resistance and Flame Retardant Labels

Certain cables are designed to be flame-resistant or low-smoke (FRLS) to reduce the risk in case of a fire. These cables are critical in places like hospitals, data centers, & other high-risk environments.

6. Certification Marks

Look for well-known certifications like ISO, UL, or CE. These marks ensure the product complies with global quality and safety standards, which is a big reassurance when it comes to picking cables for safety-critical applications.

Tips for Choosing the Right Cable

Reading the labels is only one part of choosing the right cable. Here are some additional tips to help you make the best decision:

- Know the Application: Are you wiring a home, office, or an industrial plant? High-demand applications may require cables with higher voltage & temperature ratings.

- Check for Compliance: Always make sure the cable meets both the UAE’s electrical safety codes and international standards.

- Consider Environmental Factors: If the cable will be used outdoors or in tough environments, you might want UV-resistant or armored cables.

- Evaluate Your Supplier: Work with trusted electrical cable suppliers to ensure you are getting genuine, high-quality products with reliable customer support.

- Plan for the Future: It is often a good idea to choose cables with a slightly higher capacity than you currently need, so you’re ready for any future expansion.

Suggested Read-Understanding Voltage Ratings in Electrical Cables

The Role of Electrical Cable Suppliers

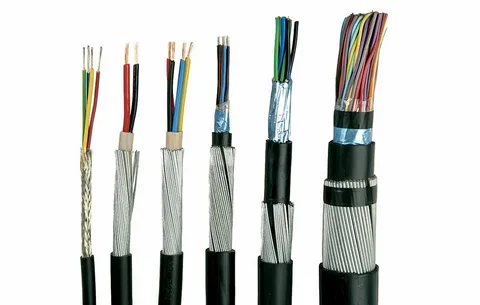

Electrical cable suppliers play an essential role in helping you get the right cables for your wants. They provide access to a wide range of products, from basic residential cables to heavy-duty industrial cables. A good supplier not only offers a variety of cables but also gives guidance on which cables are best for your specific application.

Picking a reputable supplier ensures that the cables you’re buying are compliant with local & international standards. Plus, they often give after-sales support, including installation advice, delivery, & even warranty services, making your life a whole lot easier.

Common Mistakes to Avoid

Even if you’re familiar with standards & labels, mistakes can still happen. Here are a few things to watch out for:

- Ignoring Standards: Do not cut corners by using uncertified cables to save money—it could lead to accidents or non-compliance penalties.

- Incorrect Sizing: Using cables that are too small for the job can lead to overheating, while cables that are too large are a waste of money.

- Mismatched Insulation: Using the wrong insulation for the environment (like using PVC where heat resistance is needed) can shorten the cable’s lifespan.

- Overlooking Certification: Always check the certifications on the cables. This ensures they meet the safety & quality standards you need.

By avoiding these common mistakes, you will enhance both the safety & efficiency of your electrical systems, ensuring long-term reliability.

Conclusion

Understanding electrical cable standards & labels is key to choosing the right cables for your project, whether you are working on a small residential setup or a large industrial installation. From voltage ratings to insulation types & certifications, every label gives you a must information to make informed decisions.

If you are looking for reliable, certified electrical cables, Al Arz Electrical Ware Trading offers a wide range of high-quality products, expert advice, & excellent customer service, making them a trusted partner for all your electrical needs.